Streamlining Optical Fibre Production with the Advanced Optical Fibre Diameter Analyser

Streamlining Optical Fibre Production with the Advanced Optical Fibre Diameter Analyser

Blog Article

How an Optical Fibre Diameter Analyser Enhances Quality Control in Fibre Manufacturing

The assimilation of an Optical Fibre Diameter Analyser into Fibre manufacturing processes represents a significant advancement in quality control techniques. By offering real-time, exact dimensions of Fibre diameters, this technology resolves the critical requirement for uniformity in production standards.

Importance of Fibre Diameter Measurement

Precise measurement of Fibre Diameter is vital in the area of optical Fibre technology, as it straight influences the efficiency and integrity of Fibre optic systems. The Diameter of an optical Fibre influences its light-carrying capability, depletion, and overall transmission effectiveness. Accuracy in determining Fibre Diameter guarantees that the optical homes are maintained within specified tolerances, which is important for optimal signal honesty.

Variations in Fibre Diameter can cause enhanced losses due to scattering and modal diffusion, impacting the top quality of information transmission. In high-speed interaction systems, such discrepancies can cause considerable destruction of signal quality, leading to information mistakes and decreased efficiency. Consistent Fibre Diameter is crucial for compatibility with connectors and splicing technologies, which are important components of Fibre optic networks.

Quality assurance procedures in Fibre production greatly count on precise Diameter measurements to ensure compliance with market standards. By executing robust dimension techniques, suppliers can enhance product integrity, decrease waste, and boost total system performance. Hence, the importance of Fibre Diameter dimension can not be overstated, as it acts as a foundation in the advancement of optical Fibre innovation and its applications in modern-day interaction networks.

Just How the Analyser Works

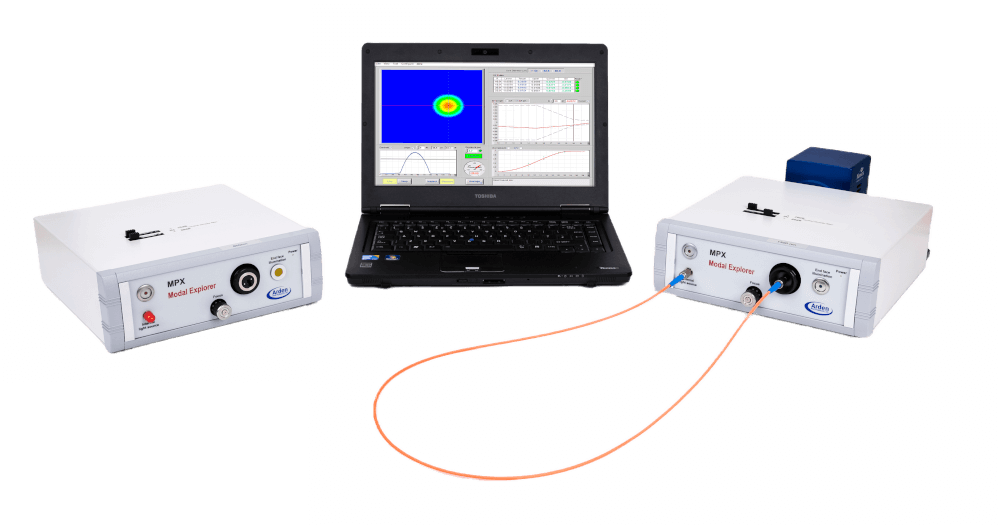

The effective measurement of Fibre Diameter depends on advanced logical techniques that make sure precision and integrity in optical Fibre production (optical fibre diameter analyser). The Optical Fibre Diameter Analyser uses a mix of laser innovation and progressed photo handling formulas to accurately evaluate the Diameter of fibres as they are produced

Initially, a laser beam is directed at the relocating Fibre, creating a cross-sectional darkness. The analyser captures this darkness utilizing high-resolution video cameras placed purposefully along the production line. The recorded pictures are after that refined in real-time to identify the Fibre's Diameter with extraordinary accuracy.

The system makes use of advanced algorithms that account for numerous aspects, consisting of variations in light strength and environmental problems, to boost measurement dependability. It can identify minute modifications in Diameter, such as variations that could occur during the production procedure.

Moreover, the analyser can managing several fibres at the same time, increasing throughput without compromising accuracy. By supplying instant feedback on the Diameter, the Optical Fibre Diameter Analyser plays an essential function in maintaining rigid high quality control requirements, making sure that the final product satisfies sector specifications and customer needs.

Benefits of Real-Time Tracking

While typical techniques of keeping an eye on Fibre Diameter often include time-consuming post-production checks, real-time tracking dramatically boosts the effectiveness and high quality of optical Fibre production. optical fibre diameter analyser. This proactive method allows manufacturers to recognize variances in Fibre Diameter as they occur, rather than waiting until manufacturing is full to assess high quality

By constantly determining the Diameter throughout manufacturing, suppliers can ensure that the fibers fulfill rigid specs, causing lowered irregularity and boosted uniformity. Real-time monitoring also makes it possible for prompt rehabilitative actions to be taken, lessening waste and avoiding malfunctioning fibres from going into the supply chain.

Additionally, this technology facilitates boosted data collection and evaluation, giving insights right into production trends and possible areas for renovation. Such data-driven decision-making useful site equips makers to maximize procedures and preserve high criteria of quality assurance.

On top of that, real-time monitoring promotes a society of continuous renovation within the manufacturing environment. Workers are more engaged when they can see the effect of their operate in real-time, leading to increased liability and a commitment to excellence. Generally, the execution of real-time tracking systems in optical Fibre production converts to superior product quality and raised consumer complete satisfaction.

Effect On Manufacturing Effectiveness

Executing optical Fibre Diameter analysers substantially improves production effectiveness by simplifying the production process. These devices facilitate continual surveillance of Fibre Diameter, allowing suppliers to identify variances in real-time. By determining incongruities immediately, production lines can be changed quickly, minimizing downtime and lowering the chance of producing malfunctioning items.

Furthermore, the combination of these analysers into the manufacturing workflow allows far better resource allotment. With precise Diameter dimensions, operators can enhance product use, ensuring that resources are not squandered on flawed fibres. This precision also adds to much less rework and ditch, ultimately decreasing manufacturing costs.

The automation given by optical Fibre Diameter analysers minimizes reliance on hands-on assessments, which are frequently time-consuming and vulnerable to human mistake. Because of this, staff members can concentrate on even more critical tasks, boosting total performance.

Additionally, the information generated from these analysers can notify procedure improvements and help with far better decision-making. By evaluating trends in Fibre Diameter variants, manufacturers can implement aggressive measures to boost production strategies and maintain consistent high quality. In recap, optical Fibre Diameter analysers play a vital duty in increasing production efficiency, resulting in better outcome and enhanced success.

Study and Success Stories

Throughout numerous markets, situation research studies highlight the transformative effect of optical Fibre Diameter analysers on production procedures. One famous instance is a leading telecoms company that faced obstacles with irregular Fibre diameters, leading to raised being rejected prices. By incorporating an optical Fibre Diameter analyser, the firm accomplished real-time monitoring of Fibre measurements, causing a 30% decrease in problems and considerable cost financial savings.

Additionally, a research study establishment focusing on advanced products used optical Fibre Diameter analysers to improve their experimental procedures. The analyser's capability to give in-depth insights right into Fibre uniformity allowed the development of cutting-edge materials with enhanced efficiency qualities.

These success tales underscore the crucial duty of optical Fibre Diameter analysers in enhancing quality assurance, improving manufacturing efficiency, and driving innovation throughout varied industries.

Conclusion

Finally, the Optical Fibre Diameter Analyser plays a pivotal function in improving quality assurance within Fibre production. By offering specific, real-time measurements and facilitating instant restorative activities, this modern technology substantially reduces irregularity and minimizes waste. The application of such advanced tools fosters a culture of continuous improvement and functional effectiveness, inevitably making certain conformity with industry standards and maintaining competitiveness. As demonstrated via different instance researches, the analyser confirms essential for attaining exceptional item quality in Fibre production.

The implementation of optical Fibre Diameter analysers enabled for rigid high quality control, making certain that the generated fibers met exacting industry requirements.In verdict, the Optical Fibre Diameter Analyser plays an essential function in improving quality control within Fibre manufacturing.

Report this page